Really great nippers !

Starrett Nippers are fantastic tools to cut effortlessly and very accurately glass, smalti, ceramic or stone no thicker than 1/4″. These tools were originally developed to cut hard tempered steel wire such as spring steel or piano wire. Their special designs provides powerful leverage for efficient and clean cutting of tiles of different thicknesses.

Starrett nippers come in 2 sizes :

A smaller 1X-5 1/2 model (list price $ 294.00)

A bigger 1 x 7 model (list price $ 391.00)

Adjustable jaws

One very interesting feature of these nippers is that you can adjust the gap between their jaws to very easily cut tiles of different thicknesses.

If you would only get one of these nippers I would recommend you get the 7” model. Personally, I own 2 of the 5 ½ “ model and one 7” and I am considering getting a second 7″. I am one of these people who never has enough tools…

Now, If you consider the list price of these tools, that brings the total value of my present tools close to $1,000.00. But of course I did not spend that kind of money on 3 pairs of pliers…

Buying used nippers…

Because these tools have been around for many years, they are commonly found on e-bay at pennies on the dollar. You can find good deals around $35.00, including shipping.

If you decide to purchase these tools used, you want to make sure their jaws will work for you; which means 2 things :

- The jaws are not chipped.

- The jaws are of the straight edge type.

So basically you need a picture showing the quality and type of the cutting edge.

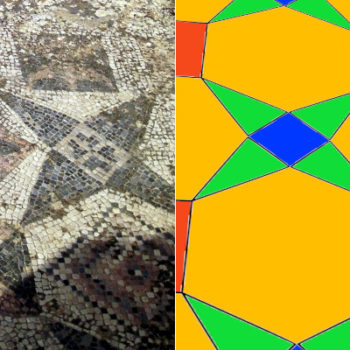

This is what you want :

Avoid edges like these :

Carbide vs Steel

While the new versions of Starrett nippers are equipped with tungsten carbide jaws, older versions were sold with hard steel jaws.

Tungsten Carbide is a very hard but brittle material. It stays sharp much longer than hard steel and does not wear much out but can chip, and once chipped is difficult to sharpen back. Personally, when it comes to straight cutting edges I would rather have hard steel than carbide – it is different for rounded cutting edges, but this is not the purpose of this article. And so this was an additional reason why I purchased used nippers.

In a next article I’ll review other types of nippers, some of them equipped with carbide jaws.